Amcor

Amcor

🏭 Europe and North America

What we like about Amcor: A more traditional plastic supplier than most on this list, but we included Amcor because they’re well equipped to handle mono-material flexible films with 25-30% PCR (tougher than it sounds!).

PLA/PE Bags and Pouches

For some film products, Amcor can adjust percentages of each material to meet compostability standards. Options for recycled PE.

-

It seems like Amcor takes pride in the clarity potential and “crispness” of many of their films.

They have films to meet many applications, especially in food: from produce to dairy and dry goods.

-

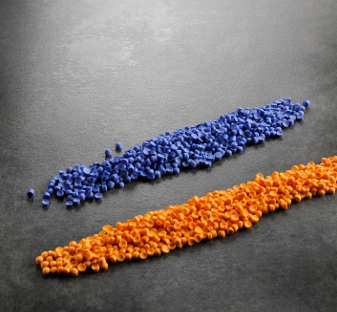

Amcor offers plastic bags made from a mix of PE (polyethylene, fossil-fuel based) and PLA (polylactic acid, bio-based).

Their PLA is derived from sugarcane, and a film made from a higher percentage of PLA can be composted, but likely in an industrial facility. Since PLA is bio-based, the more of it in a film, the less reliance that bag has on fossil fuels.

While PE (polyethylene) is derived from fossil fuels, films made with higher percentages of recycled PE have less reliance on virgin fossil fuels, and play a role in capturing and recycling plastic waste. Unfortunately, most recycling facilities aren’t equipped to recycle plastic films, so the vast majority (over 90%) end up in landfills.

-

Compostable PLA film: They carry a lot of plastic films that are made from a PLA which they claim is compostable. Be sure to ask for certifications to understand if they’re compostable in industrial or home setups. The crispness and clarity of the plastic leads us to believe that it’s industrially compostable.

PE film: In 2021, the US recycled less than 6% of its plastic waste, according to a study by Beyond Plastics.

Amcor’s PE bags are made of either LDPE or HDPE. Either way, it’s formed into a thin film which has a lower recycling rate than rigid plastics because most sorting and recycling facilities are not equipped to process it.

While plastics with the resin codes #1 and #2 (PET and HDPE) have a higher likelihood of being recycled, plastic as a whole has a very low likelihood of actually being recycled. This is due to several factors including the lack of recycling infrastructure, the number of plastic types, the sheer volume of plastic waste, and the quick degradation of the polymers in recycling. Even if plastic ends up in a recycling bin, most of it will end up in landfills or oceans.

To minimize the amount of plastic sent to landfills, use paper-based or glass alternatives, or opt for refillable or practically reusable designs.

-

Compostable PLA film: Bioplastics look and feel like traditional plastic. Proper disposal information should be an important part of the design so that they don't end up in the wrong waste stream. Let customers know if they should recycle or compost the plastic.

Composting is the best case scenario, but it's good to let customers know that if they can't compost it, that the plastic should be reused or thrown in with the trash. Tossing bioplastic in with recycling just adds an extra step on the way to landfill.

You could consider a takeback program. If you can work with an industrial composter that accepts bioplastic, you can bulk compost your packaging on behalf of customers."

PE film: Use discretion when using plastic resin codes (the recycling symbol surrounding a number). They can be misleading because they imply that a type of plastic is recyclable, when in many cities that's not the case. Plastics #1 and #2 (PET and HDPE) are most widely accepted for recycling, unless they’re made into plastic film.

On your design, it's ideal to indicate the plastic type and encourage customers to look into the rules for their city before recycling.

Polyethylene Laminate Bags and Pouches

With many options for lower impact laminates including recycled content, metal free, and mono-material.

-

It seems like Amcor takes pride in the clarity potential and “crispness” of many of their films.

They have films to meet many applications, especially in food: from produce to dairy and dry goods.

-

While PE (polyethylene) is derived from fossil fuels, films made with higher percentages of recycled PE have less reliance on virgin fossil fuels, and play a role in capturing and recycling plastic waste.

Traditional laminates pose a specific issue when it comes to disposal because they’re often made from multiple types of plastic and/or metalized film. By offering mono-material and metal-free options, Amcor is making films that are viable for recycling.

Unfortunately, most recycling facilities aren’t equipped to recycle plastic films, so the vast majority (over 90%) end up in landfills.

-

In 2021, the US recycled less than 6% of its plastic waste, according to a study by Beyond Plastics.

Amcor’s PE bags are made of either LDPE or HDPE. Either way, it’s formed into a thin film which has a lower recycling rate than rigid plastics because most sorting and recycling facilities are not equipped to process it.

While plastics with the resin codes #1 and #2 (PET and HDPE) have a higher likelihood of being recycled, plastic as a whole has a very low likelihood of actually being recycled. This is due to several factors including the lack of recycling infrastructure, the number of plastic types, the sheer volume of plastic waste, and the quick degradation of the polymers in recycling. Even if plastic ends up in a recycling bin, most of it will end up in landfills or oceans.

To minimize the amount of plastic sent to landfills, use paper-based or glass alternatives, or opt for refillable or practically reusable designs.

-

Use discretion when using plastic resin codes (the recycling symbol surrounding a number). They can be misleading because they imply that a type of plastic is recyclable, when in many cities that's not the case. Plastics #1 and #2 (PET and HDPE) are most widely accepted for recycling, unless they're made into plastic film.

On your design, it's ideal to indicate the plastic type and encourage customers to look into the rules for their city before recycling.

Poly Bags & Films

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Trays & Inserts

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

Paper Mailers

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Cushioning

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

Jars & Bottles

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

Glass bottles and jars for food and beverage, made from an average of 60% recycled content.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Glass containers made from high percentages of recycled glass and ocean-bound plastic caps.

Glass manufacturer, specializing in cosmetics and perfume, with options for plastic closures.

Jars and bottles, with options for recycled content in addition to mono-material pouches.

Corrugated

US-based corrugated manufacturer with 100% recycled content Envirokraft line. Strongest TikTok game in the corrugated manufacturing world.

Corrugated manufacturer with options for a water and grease barrier that’s compatible with paper recycling.

US-based supplier carrying a good array of stock options and are capable of doing custom solutions.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Folding Cartons

Utah PaperBox is a folding carton and rigid packaging manufacturer based in Salt Lake City.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Specializing in paperboard boxes, folding cartons, and collateral, with options for 100% recycled paper.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Food Service

Large catalog of low minimum compostable options. Be wary of PLA with further research.

Inks & Coatings

Raw Materials

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Labels

High-performing self-adhesive paper and film products for an extensive set of end-uses, with a range of fossil fuel-free options.

Quality custom labels, shrink sleeves, and hang tags with fast turn around for a variety of industries.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Specialty Papers

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.