Elk Packaging

Elk Packaging

🏭 US (California)

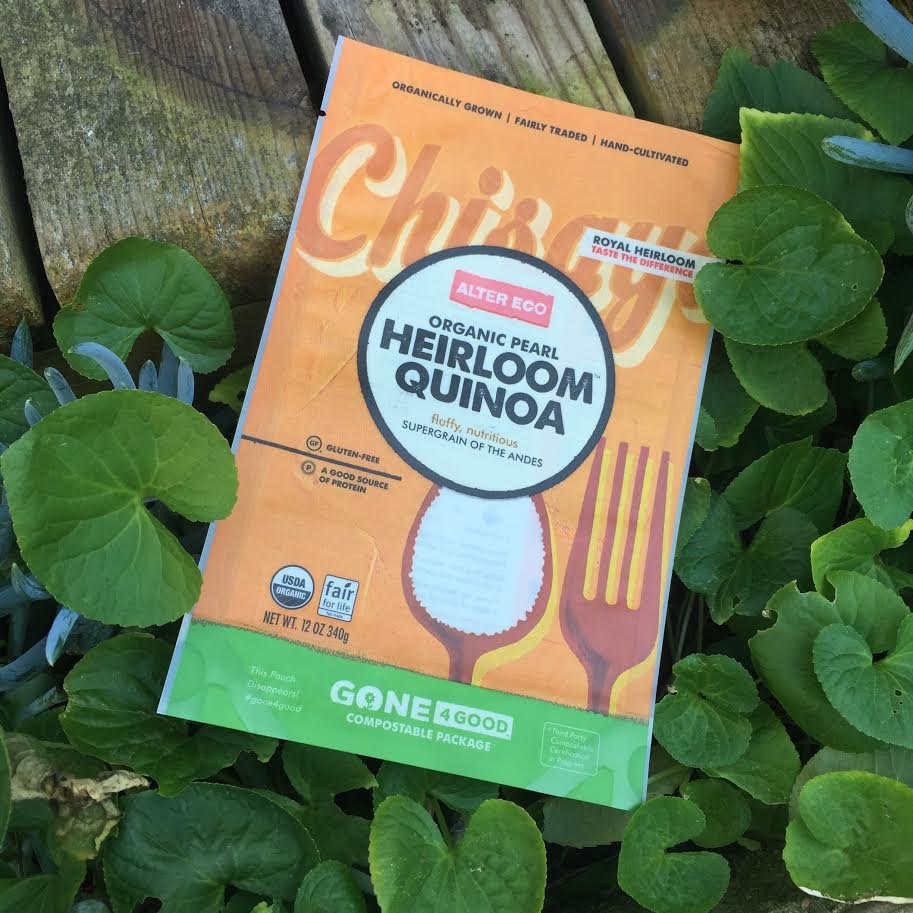

What we like about Elk Packaging: Their compostable bioplastic pouch can replace laminate pouches which are traditionally non-recyclable.

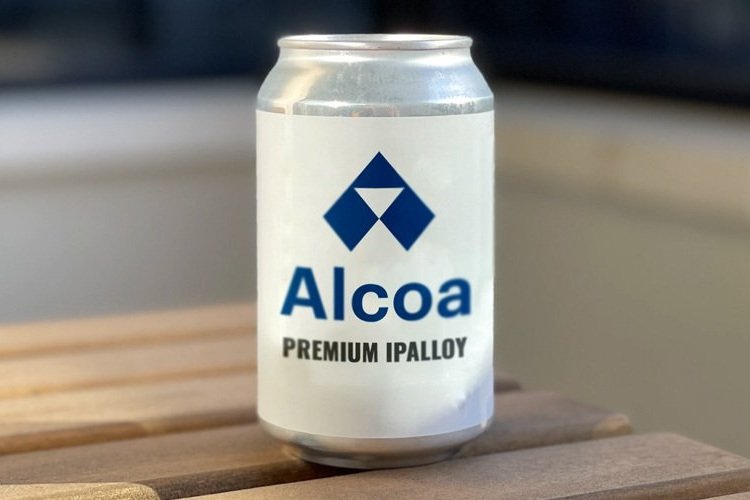

Bioplastic Blend Pouches

patent-pending laminate alternative, made from birch and eucalyptus wood pulp, and non-GMO corn. Printed with non-toxic ink.

-

More rigid than poly mailer, with options for gussets so that they stand up.

-

Bioplastics are derived primarily from renewable materials from plants or animals, instead of fossil fuels which are not renewable. Some bioplastics may have fossil fuel additives to enhance certain performance properties like flexibility.

-

Elk Packaging claims that their pouches are compostable, but it’s unclear if they can be composted in industrial settings or at home.

We don’t have information on their certifications. Ask for certifications to verify proper compostability.

If they’re not composted, they should be disposed of with regular trash.

-

Bioplastics look and feel like traditional plastic. Proper disposal information should be an important part of the design so that they don't end up in the wrong waste stream. Let customers know if they should recycle or compost the plastic.

Composting is the best case scenario, but it's good to let customers know that if they can't compost it, that the plastic should be reused or thrown in with the trash. Tossing bioplastic in with recycling just adds an extra step on the way to landfill.

You could consider a takeback program. If you can work with an industrial composter that accepts bioplastic, you can bulk compost your packaging on behalf of customers.

Folding Cartons

-

Folding cartons are made from a rigid paperboard. The paperboard used for folding carton is often a gray kraft color on the inside, with a more raw texture. On the outside, you can have a variety of colors and finishes, which can dictate the look of the final print.

-

Paper is made from plants — a renewable resource. Most paper is made from trees. Trees sequester carbon, which is ultimately released back into the air at the paper's end of life when it biodegrades or is composted or incinerated.

Paper is lightweight in shipping and can be engineered for structural stability with flat pack shipping.

For more transparent sourcing, suppliers may source paper that has an FSC certification. The paper and forest industry created FSC certifications to set standards like stricter restrictions on clear cuts and pesticide use.

-

The best afterlife for most paper products — from collateral to boxes — is recycling. Most paper fibers can be recycled more than five times. Paper with tape or stickers can still be recycled, because non-paper materials are sifted out in the recycling process.

-

Printed designs will take on the finish of the paper. For a shiny finish, you’ll need to inquire about added coatings. Coatings may also be necessary if your packaging needs extra water resistance.

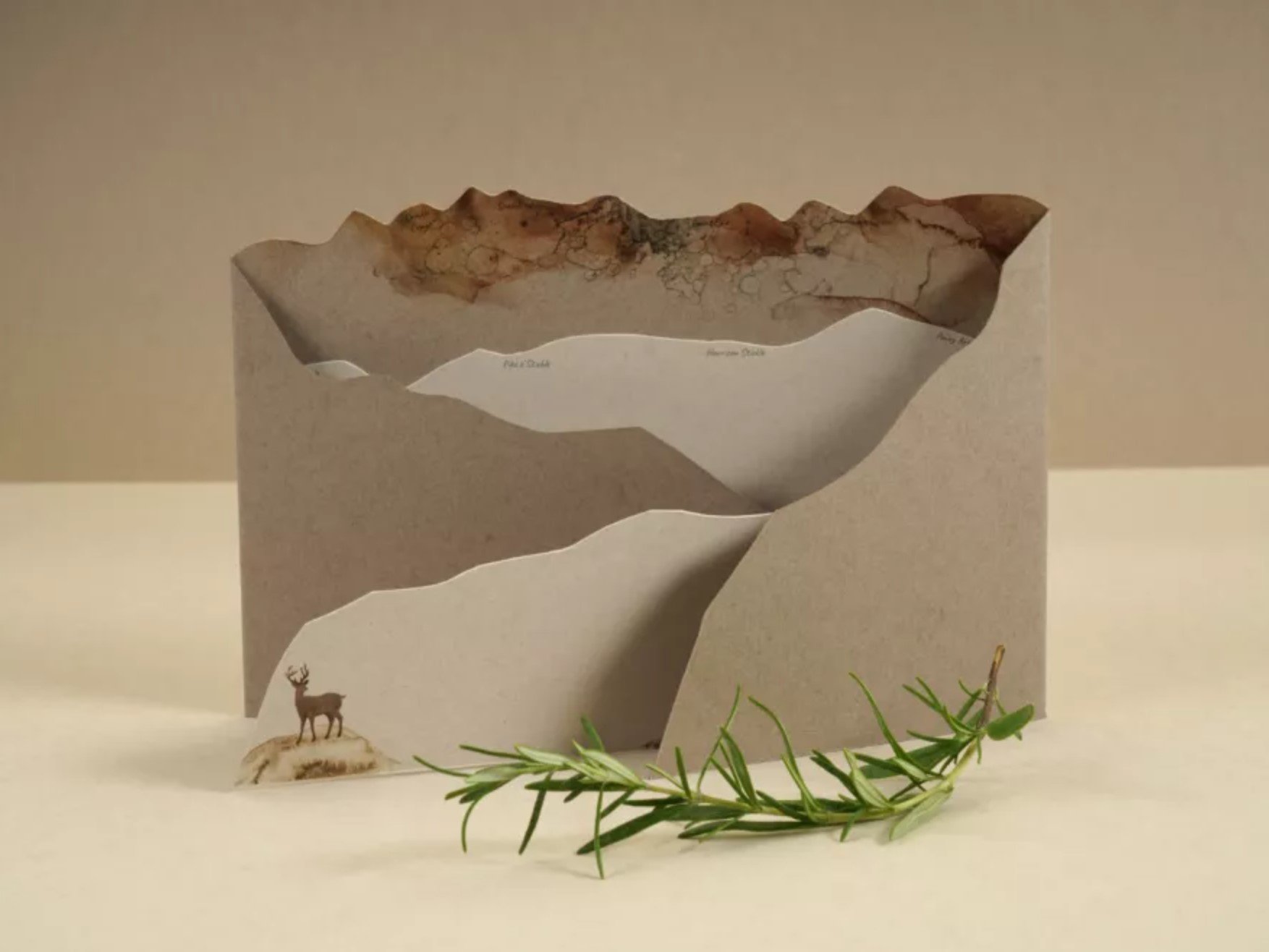

Corrugated Boxes

-

Corrugated boxes and inserts are made from corrugated board which has three kraft paper layers to make a rigid board — two liners and a corrugated layer in between.

Corrugated thicknesses are called flutes. Depending on the liner thicknesses, larger flutes (A) can make a board appear more wavy and smaller flutes (E-G) can make a board appear more smooth.

Most graphics are printed direct on the kraft paper. The ink soaks into the paper, so the corrugated maintains its matte, textured feel. There are coatings and coated substrates available to make boxes look shiny and feel more slick, in addition to making the inks appear more vibrant.

-

These paper boxes are made from trees, which are a renewable resource. In the first leg of shipping to a distributor, boxes ship flat, taking up less space in transit. After it’s built and filled, the box will have a set volume in shipping.

Corrugated board is made from paper which is easily recycled or composted (see Disposal).

For more transparent sourcing, suppliers may source paper that has an FSC certification. The paper and forest industry created FSC certifications to set standards like stricter restrictions on clear cuts and pesticide use.

-

The best afterlife for most paper products — from collateral to boxes — is recycling. Most paper fibers can be recycled more than five times. Paper with tape or stickers can still be recycled, because non-paper materials are sifted out in the recycling process.

-

Typically, you can print on the entirety of a box, from edge to edge. Printed designs will match the finish of the paper.

For a shiny finish, you’ll need to inquire about added coatings. Coatings may also be necessary if your packaging needs extra water resistance.

Poly Bags & Films

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Trays & Inserts

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

Paper Mailers

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Cushioning

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

Jars & Bottles

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

Glass bottles and jars for food and beverage, made from an average of 60% recycled content.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Glass containers made from high percentages of recycled glass and ocean-bound plastic caps.

Glass manufacturer, specializing in cosmetics and perfume, with options for plastic closures.

Jars and bottles, with options for recycled content in addition to mono-material pouches.

Corrugated

US-based corrugated manufacturer with 100% recycled content Envirokraft line. Strongest TikTok game in the corrugated manufacturing world.

Corrugated manufacturer with options for a water and grease barrier that’s compatible with paper recycling.

US-based supplier carrying a good array of stock options and are capable of doing custom solutions.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Folding Cartons

Utah PaperBox is a folding carton and rigid packaging manufacturer based in Salt Lake City.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Specializing in paperboard boxes, folding cartons, and collateral, with options for 100% recycled paper.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Food Service

Large catalog of low minimum compostable options. Be wary of PLA with further research.

Inks & Coatings

Raw Materials

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Labels

High-performing self-adhesive paper and film products for an extensive set of end-uses, with a range of fossil fuel-free options.

Quality custom labels, shrink sleeves, and hang tags with fast turn around for a variety of industries.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Specialty Papers

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.