Pulpac

Pulpac

🏭 Sweden

What we like about Pulpac: They offer high-speed manufacturing that’s comparable with the speed of plastic production. They’re open to exploring R&D on new products like paper bottles.

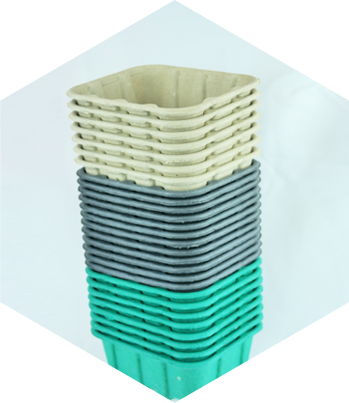

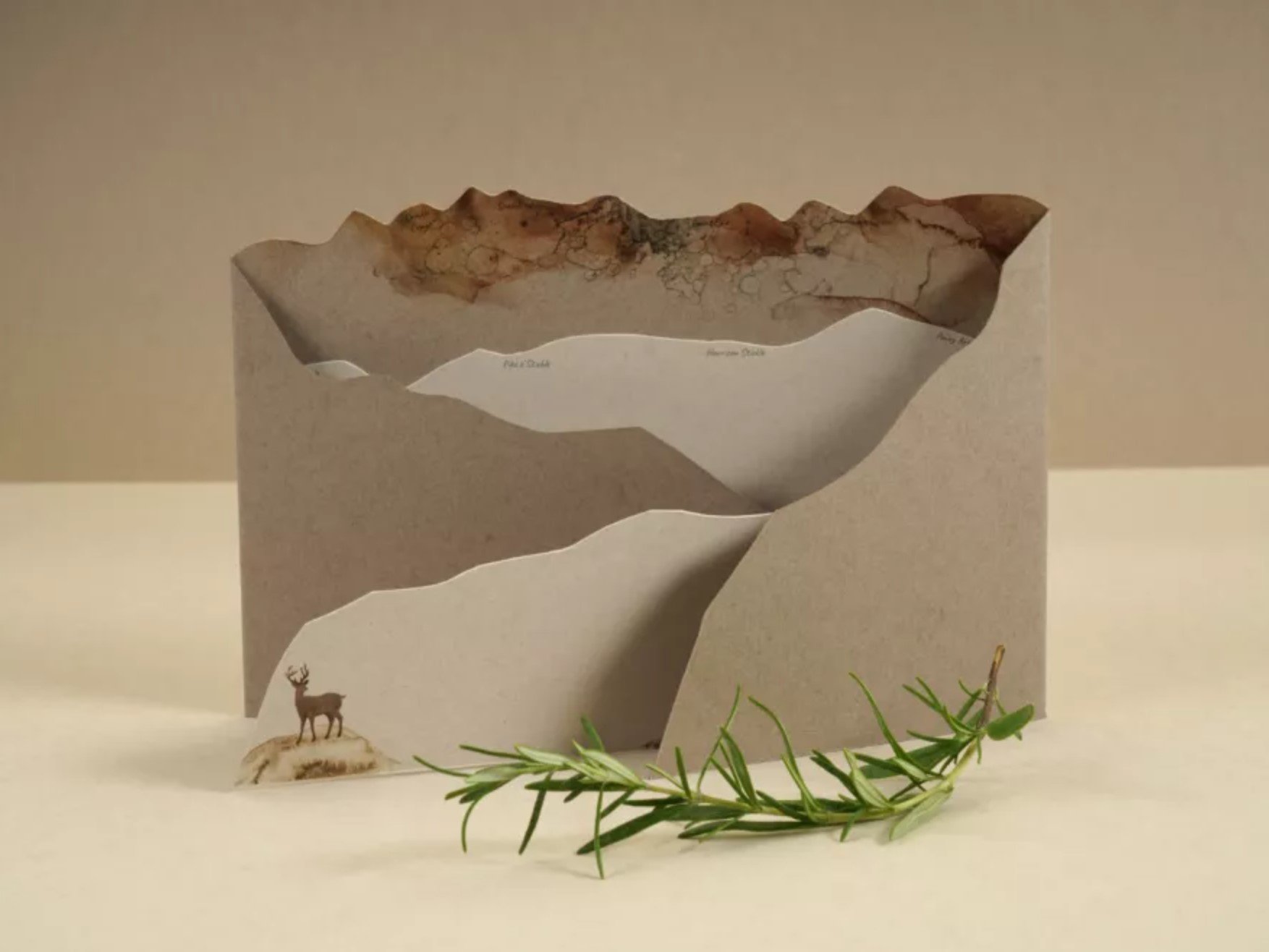

Pulp Trays

Various structure options, including food service.

-

There may be variations in smoothness and thickness, but molded paper pulp looks and feels similar to paper egg cartons.

-

Pulpac’s molded paper is made from paper or pulp that’s broken up into fibers. Molded paper can work as a bio-based alternative to plastic that relies on renewable resources instead of fossil fuels.

Molded pulp trays take the biggest sustainability hit when it comes to energy requirements, because they typically require high heat to dry in manufacturing. Pulpac has a more unique manufacturing process, so it’s unclear if they also require high heat.

For more transparent sourcing, suppliers may source paper that has an FSC certification. The paper and forest industry created FSC certifications to set standards like stricter restrictions on clear cuts and pesticide use.

-

The best afterlife for most paper products — from collateral to boxes — is recycling. Most paper fibers can be recycled more than five times. Paper with tape or stickers can still be recycled, because non-paper materials are sifted out in the recycling process.

-

Pulpac can manufacture a wide variety of structures to include embossing or debossing. Print and coatings are also an option.

Printed designs will match the finish of the paper. For a shiny finish, you’ll need to inquire about added coatings. Coatings may also be necessary if your packaging needs extra water resistance.

Trays & Inserts

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

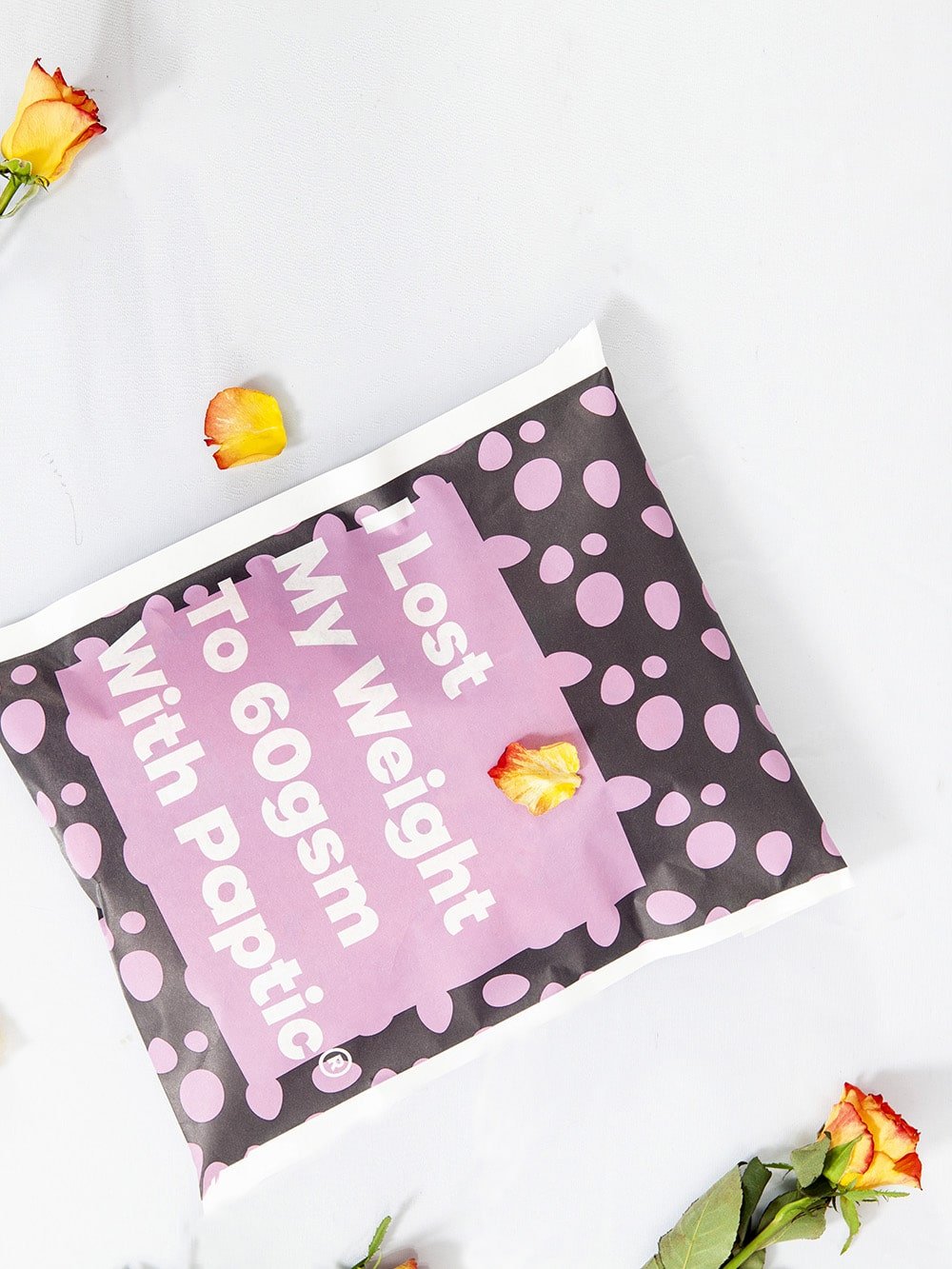

Poly Bags & Films

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Paper Mailers

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Cushioning

Large offering of stock paper and plastic ecommerce solutions, with impressive PCR rates.

Specializes in corn starch foam, a dissolvable, home-compostable alternative to plastic foam and insulation.

Jars & Bottles

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

Glass bottles and jars for food and beverage, made from an average of 60% recycled content.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Glass containers made from high percentages of recycled glass and ocean-bound plastic caps.

Glass manufacturer, specializing in cosmetics and perfume, with options for plastic closures.

Jars and bottles, with options for recycled content in addition to mono-material pouches.

Corrugated

US-based corrugated manufacturer with 100% recycled content Envirokraft line. Strongest TikTok game in the corrugated manufacturing world.

Corrugated manufacturer with options for a water and grease barrier that’s compatible with paper recycling.

US-based supplier carrying a good array of stock options and are capable of doing custom solutions.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Folding Cartons

Utah PaperBox is a folding carton and rigid packaging manufacturer based in Salt Lake City.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Specializing in paperboard boxes, folding cartons, and collateral, with options for 100% recycled paper.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Personal care packaging like bottles and tubes made from 100% post consumer recycled plastic, sugarcane, or aluminum.

Food Service

Large catalog of low minimum compostable options. Be wary of PLA with further research.

Inks & Coatings

Raw Materials

Industrially compostable bamboo bioplastic jars and bottles for personal care products.

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.

Biopolymer extracted from nature to take many forms: films, rigid containers, and more.

Labels

High-performing self-adhesive paper and film products for an extensive set of end-uses, with a range of fossil fuel-free options.

Quality custom labels, shrink sleeves, and hang tags with fast turn around for a variety of industries.

Manufacturer of boxes and paper mailers that also specializes in high quality adhesive and labels.

Expansive catalog of stock and custom ecommerce packaging, from mailers and boxes to tape and labels.

Selection of home compostable plastic mailers and bags. They also carry compostable tape and labels.

Specialty Papers

European manufacturer offering recyclable paper packaging with barrier protection against water and grease.

Folding cartons and collateral made from paper blend made from 50% hemp 50% recycled paper.